Over-engineering. It happens more than you might believe. Often, it’s driven by good intentions, such as ensuring structural integrity and wind load resistance. Unfortunately, it’s all too common in traditional fiber-cement cladding systems. That’s because these older systems typically require 16″ on-center (OC) framing. Inches matter with stud spacing. Closer stud spacing increases material use and labor time. It also adds cost and complexity, especially in large facade applications.

As a leader in rainscreen innovation, efficiency and performance-based engineering, Sto has been actively working on solutions to overengineering, with a focus on fiber-cement applications. StoVentec® Fiber Cement is the result of those efforts.

StoVentec® Fiber Cement: A Smarter Structural Approach

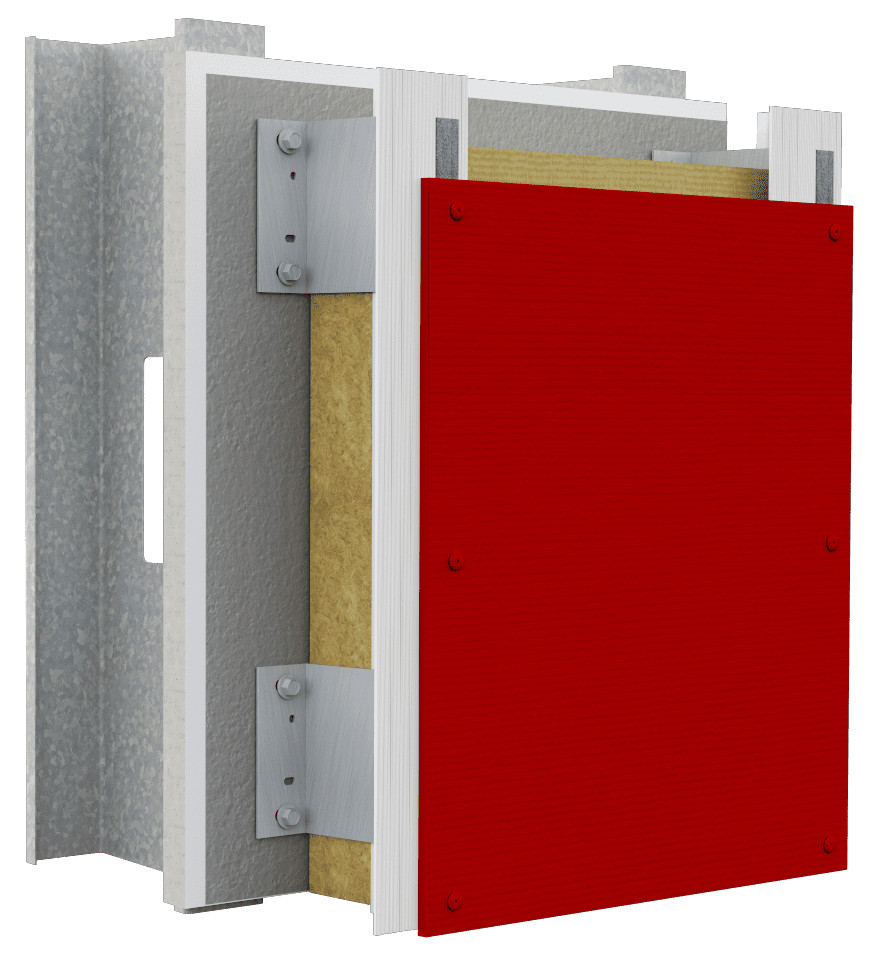

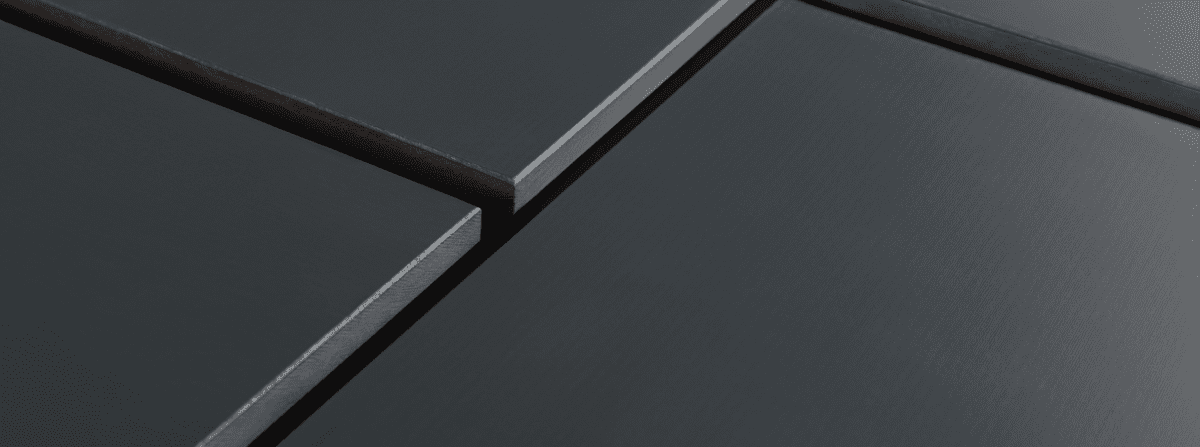

A forward-thinking solution that helps architects and contractors reduce overdesign and optimize facade performance, StoVentec® Fiber Cement offers unparalleled versatility and design freedom for your projects. As an extension of our trusted Rainscreen® systems, this durable, aesthetically flexible cladding solution empowers architects to create facades as unique as the buildings they design.

One of the design tools available with this system is the StoVentec Fiber Cement Design Guide and Detail Booklet. This powerful guide enables lean framing layouts with 24″ on-center spacing. That’s an 8” difference compared to traditional fiber-cement systems, reducing material requirements by up to one-third! The benefits of this lean framing approach are clear:

- Material Efficiency: Fewer studs and connection points mean lower material costs and lighter wall assemblies without sacrificing performance or durability

- Labor Savings: Wider spacing reduces installation time and simplifies layout coordination between trades

- Smarter Engineering: Reduces overdesign and optimizes facade performance, saving time and money

- High Performance: StoVentec Fiber Cement still meets or exceeds performance standards for durability, fire and moisture management

- Design Flexibility: Allows architects to specify fiber cement with the same confidence as denser framing systems, enabling clean, modern facade designs

- Competitive Advantage: Gives building owners and contractors an edge by combining efficiency with proven Sto engineering

Performance and System Validation

StoVentec® Fiber Cement maintains performance, structural stability and design flexibility while simplifying installation and reducing engineering time and costs. These aren’t talking points. They’ve been proven. StoVentec® has been rigorously tested for wind load, deflection and indention resistance, and is currently undergoing everyday impact testing.

The StoVentec Fiber Cement Design Guide and Detail Booklet provides:

- Clear parameters and documentation to verify compliance with project requirements.

- Predictable outcomes and streamlined coordination through pre-engineered, tested details

- Design tables and testing data supporting 24″ OC spacing, tested sub-framing and performance results for wind resistance and system integrity

- Details on how the system integrates with air and moisture management layers to deliver a complete, high-performance rainscreen solution from one manufacturer with a single source warranty

- Verified compatibility between the fiber cement panels, sub-framing and StoVentec components for complete system assurance

Leaner. Smarter. Stronger.

Overengineering is inefficient in all the ways we’ve outlined. It’s time to go leaner, meaner and stronger with lean framing solutions. StoVentec Fiber Cement proves that efficiency and performance can coexist, delivering high-value facades with lean framing and uncompromised quality.

To learn more about StoVentec® Fiber Cement, visit our website or contact us to speak with a representative.