Color selection in commercial applications is growing more strategic. In a recent blog post, we talked about the rise of dark colors, which add depth and dimension, creating a sense of sophistication and luxury. But if you want to ensure your color choice delivers the performance building owners expect, there are other considerations, such as whether the pigments are organic or inorganic.

Fortunately, Sto Corp. is a company obsessed with color. We love providing architects and designers with the tools they need to bring their creative visions to life. We help them balance aesthetic ambition with long-term performance through innovative materials science. We refer to it as performative aesthetics. And it means beautiful, long-lasting facades. Pigments are, of course, an important part of that equation. But what exactly is a pigment?

Pigments 101: The Basics

Pigments are not the same as dyes. Dyes are soluble colorants known for their ability to produce vibrant, intense colors. However, they are generally less resistant to fading when exposed to light, especially UV rays, compared to pigments.

Pigments, on the other hand, are finely ground, insoluble particles that produce color by scattering light. They are mixed with a liquid medium, known as a binder, to form colorant; the pigment solution used to color coatings and finishes. Colorants provide color and functional qualities, and impact UV resistance, chemical stability, and maintenance of the product.

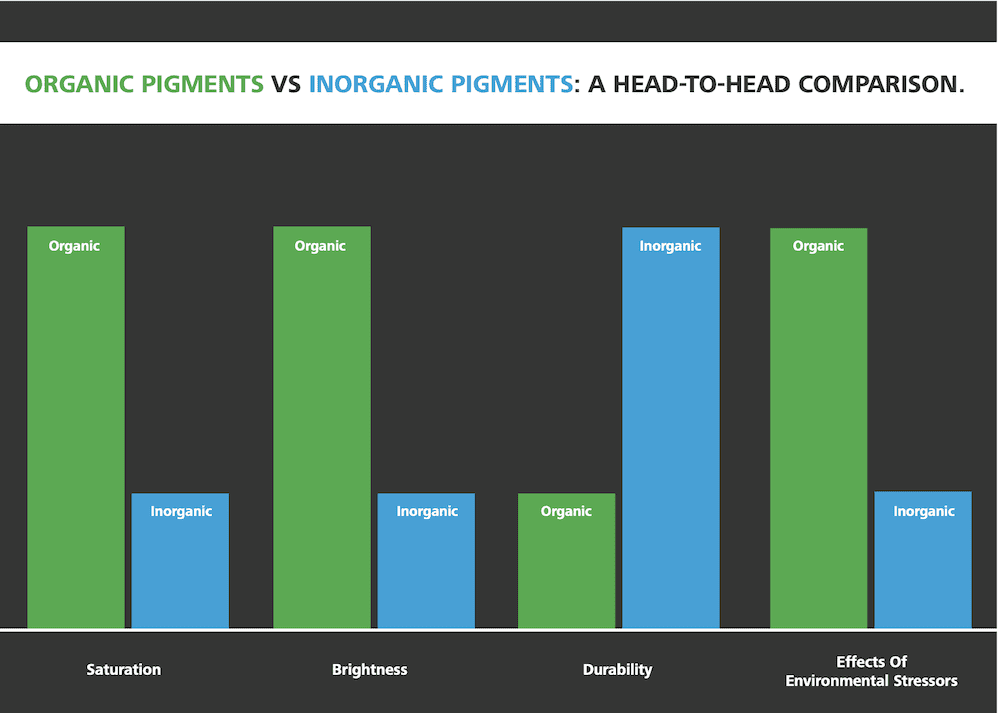

There are two main categories of colorant: organic and inorganic. There are several differences between the two. Let’s begin with organic colorants.

The Natural Brilliance of Organic Pigments

As the name implies, organic colorants are comprised of carbon-based compounds. Organic colorants are typically made with pigments, solvents, resins (binders), and other additives, including driers, hardeners, stabilizers, surfactants, and dispersants. Resins, typically dissolved in solvents, play a crucial role in forming a protective barrier against corrosion and oxidation. The color, opacity, mechanical properties, and barrier properties of the coating or finish depend on the chemical makeup of the dispersed pigments and the pigment volume concentration (PVC).

What is PVC? Pigment volume concentration (PVC) influences how likely the coating will chalk. PVC refers to the ratio of the volume of pigment particles to the total volume of the pigment and binder in the coating. Essentially, it tells you the percentage of pigment in the polymer pigment matrix. Lower PVC coatings are less prone to chalking.

Organic pigments can create brilliant colors and bold hues, such as red, teal, and magenta. The tradeoff for the brilliant colors achieved is lower UV (ultraviolet light) and heat resistance, which makes the coating prone to fading over time. Additionally, coatings with organic pigments are often more transparent in deeper bases, requiring more coats for full coverage and sealers to minimize fade resistance.

These disadvantages aside, organic pigments are the only way to achieve some vibrant and brilliant colors. Using them wisely can reduce the ongoing maintenance of your building. They are perfect for accents and for use in areas that are smaller in scope. They are less suitable for large facade areas, especially in areas prone to harsh climate conditions.

The Proven Performance of Inorganic Pigments

Inorganic pigments differ from organic pigments because they rely on minerals such as silica, alumina, and titanium dioxide, rather than carbon-based compounds. These minerals are often combined with other additives to improve adhesion, flexibility, and other performance characteristics.

Yielding more muted colors, inorganic pigments are an effective solution to environments threatened by heat, chemicals, and UV radiation. Benefits of inorganic pigments include:

- Durable, long-lasting finish

- Perfect for earth tones, whites, and muted shades

- Exceptional UV and chemical resistance

- High opacity and coverage efficiency

- Heat resistant, ideal for full facades and high-exposure environments

- Environmentally friendly

Our Approach: Integrally Colored Finishes Engineered to Perform

It may seem as if the advantages and disadvantages of organic and inorganic pigments paint a black and white picture, so to speak. But there is an easier way to navigate color selection. At Sto, we believe full system integration ensures color longevity, and innovation enables architects and designers to marry design and performance goals.

Sto offers engineered solutions that provide UV-stable coatings, such as StoColor Dryonic®, and StoColor Acryl Plus, which enable better performance with darker colors.

Our Best Advice for Specifying Color:

- Choose colors that utilize inorganic pigments for low-maintenance, long-term performance

- If organic pigments are required, consider using Sto Clear Coat Sealer as a topcoat to extend the life of your coating

- Factor in LRV (light reflectance value) and climate considerations

- Use Sto primers to protect pigments and improve opacity and coverage

- Lean on Sto’s technical support for optimized color choices and product recommendations that extend durability and enhance performance

- Consult the manufacturer for product recommendations when utilizing dark, bold colors

Parting Thoughts on Pigment

Pigments are critical to color performance in coatings. By understanding the advantages and disadvantages of organic and inorganic pigments and knowing that there are advanced coatings technical support available, you can ensure you get the aesthetic and performance you’re seeking. As part of our commitment to creative freedom, Sto has developed industry-leading tools to help create stunning facades that are durable, sustainable, and versatile.

With our advanced coatings and finishes, virtually anything is possible. Check out our project gallery to see for yourself. To speak with a member of our design team, call (800) 221-2397.