A crack is rarely just a crack. Often, it’s a warning. A red flag, signaling that there may be more going on underneath.

There are two general types of cracking: structural and surface. Surface cracking, also known as hairline cracks, are generally 1/16” wide or less; structural cracking is typically wider and deeper. What are some of the causes of cracking and what can be done to prevent them? This blog post is going to crack this topic wide open and provide answers to these questions and more. Let’s begin by looking at the root causes of cracks in commercial buildings.

Common Causes of Facade Cracking

Cracks in a facade can be caused by a wide range of things. The source of the crack can be rooted in environmental impacts. Cracks can also stem from problems inside a building. Here is a short list of the most common causes of facade cracking.

Environmental stressors may include:

- Thermal expansion and contraction – As a building heats and cools, its exterior components expand and shrink, creating stress.

- Freeze/thaw cycles – In colder climates, winter can exact a heavy toll on a building with repeated freeze/thaw events.

- Wind-driven rain and UV degradation – Environmental elements are the most frequent stressors, pounding the exterior of buildings day in and day out.

Structural and substrate-related causes may include:

- Building movement or settlement – Buildings settle over time creating stress points that lead to cracks and while buildings are designed for movement, years of movement or extreme movement outside of normal parameters can increase stress.

- Inadequate substrate preparation – Surface level protection offers one level of defense; if the substrate is left unprotected, surface cracks can penetrate deeper, faster.

- Incompatibility between facade materials – Different materials from different manufacturers don’t always work well together, sometimes leaving weak spots in a building’s envelope.

But how much damage can a crack cause? It can’t be that bad, can it? The consequences of these problems can be very real and very damaging.

The Short- and Long-Term Consequences of Cracks

Surface cracks are more than just cosmetic flaws. They can lead to serious performance issues and costly repairs. Obviously, cracks create an opportunity for moisture intrusion, which can lead to the growth of mold and mildew. Air leakage into the walls can compromise energy efficiency.

Long-term consequences may include material degradation. The constant intrusion of both water and air can damage components found within the wall cavity. The degradation of these systems can lead to more significant water intrusion and compromised climate control for the occupants. In worst-case scenarios, these failures can lead to liability and warranty issues.

But there are ways to address hairline cracks in stucco claddings that help prevent future breaches, extend the facade life, reduce lifecycle costs, and preserve aesthetics. One solution proven to proactively prevent cracks is Sto Crack Defense.

Sto Crack Defense: Engineered for Performance

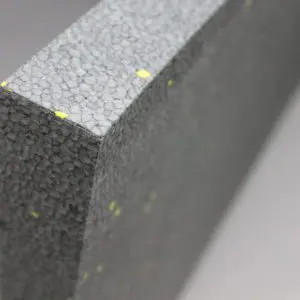

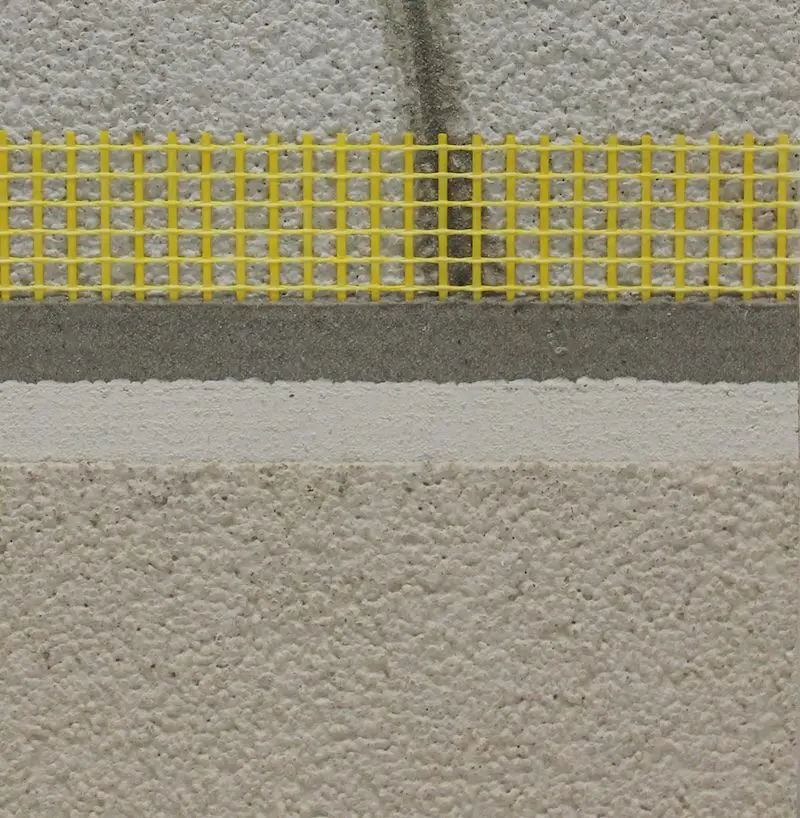

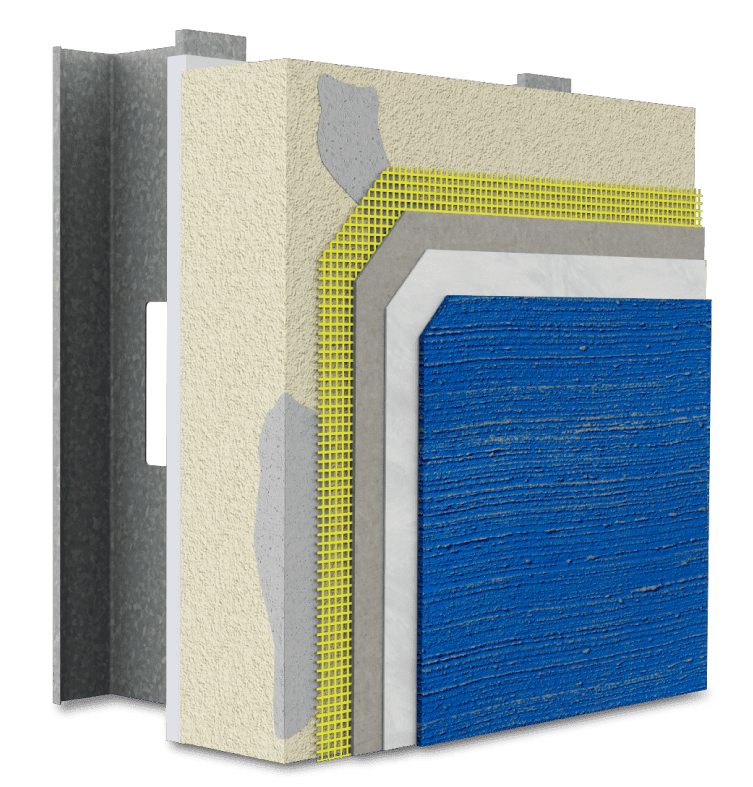

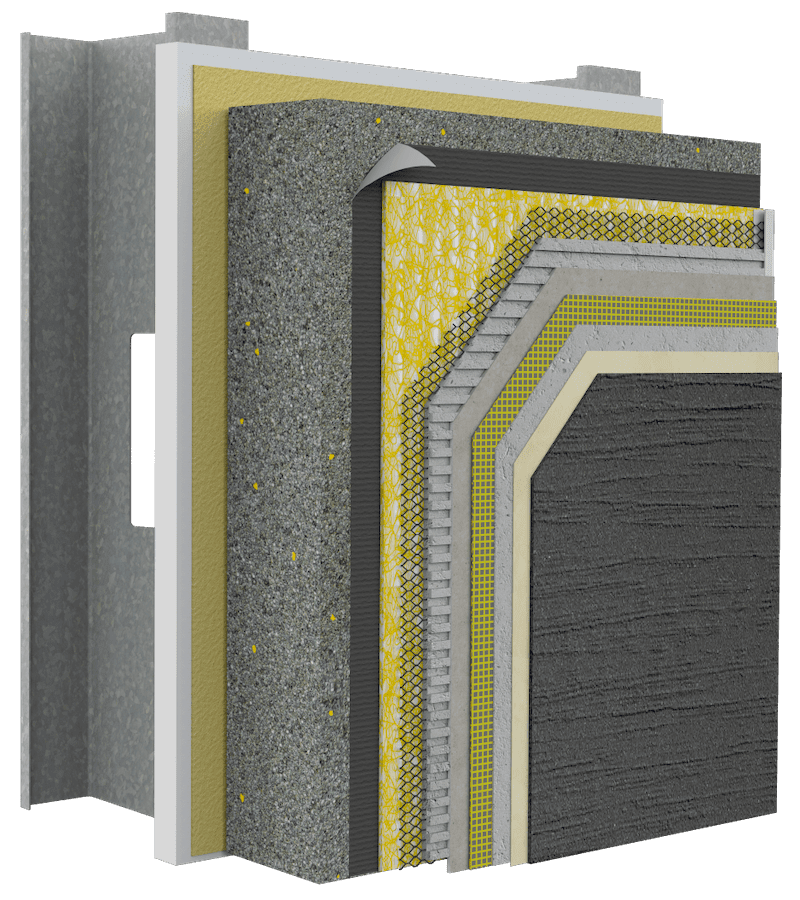

Sto’s crack prevention technologies protect your investment from the start. Sto Crack Defense, in particular, enhances the durability and longevity of stucco and other facade systems. This fortification layer consists of woven glass fiber mesh embedded in a polymer-reinforced basecoat. The technical advantages of using a crack prevention system like this include:

- Reinforcement resists cracking from stresses and movement

- Distributes load across a broader surface area

- Flexible and durable under real-world building dynamics

Sto Crack Defense is designed to work with any stucco cladding system, including our own StoPowerwall® Stucco, a stucco wall assembly with a continuous air and water-resistive barrier that combines the strength and durability of traditional stucco.

This system can be used in new builds and retrofits. For new construction, it’s an integral solution for architects and builders focused on long-term durability and aesthetics that enhance the performance of exterior wall systems from day one. In restorations and retrofits, Sto Crack Defense is ideal for preserving historic facades or repairing cracked stucco, helping to meet updated performance codes without a full tear-off.

Proactive Measures Pay Off

It’s been said that an ounce of prevention is worth a pound of cure. That certainly holds true when it comes to proactively integrating crack control measures. Here are just a few of the benefits of using crack prevention technology like Sto Crack Defense:

Reduced maintenance and repair costs:

- Fewer callbacks for cracking

- Longer service intervals before refinishing

Improved visual continuity:

- Preserves clean facade lines over time

- Avoids the “patched” look that undermines curb appeal

Sustainability bonus:

- Contributes to longevity and durability metrics in green building programs (LEED, etc.)

Crack Prevention is Value Engineering

Investing in Sto Crack Defense is a long-term strategy for a high-performance facade. Specifying Sto Crack Defense is value engineering. It saves the building owner from expensive and unnecessary repairs down the road. Stop cracks before they happen with Sto Crack Defense.

For more information about Sto Crack Defense or Sto Corp., please visit www.stocorp.com or call (800) 221-2397. To find the perfect Sto system for your project, check out the Sto System Finder.