Not all air and water-resistive barriers are created equal. Nor is there one solution that’s perfect for all projects. Choosing between a fluid-applied and a self-adhered AWRB is a performance-critical decision. While budget is always a factor, your decision should be based more on building science than on upfront cost and brand bias. You need to weigh factors such as climate, assembly complexity, and installation timing and conditions, as well as long-term durability across different building scenarios. There will be trade-offs no matter which choice you make. But you want to make your decision intentionally, with the goal of delivering the best barrier for the project to ensure long-term performance.

The purpose of this blog post is to present the differences between a fluid-applied and a self-adhered AWRB, as well as the ideal use scenarios for each, so that you can make an informed decision between the two.

The Purpose of the AWRB

Sto is proud to be a building envelope expert. As evidenced by our high-performance solutions trusted worldwide, we understand AWRBs inside and out. At the core of that expertise is the understanding that air and water are the enemies of building performance. They are constantly trying to find a way inside. The purpose of an AWRB is to stop them.

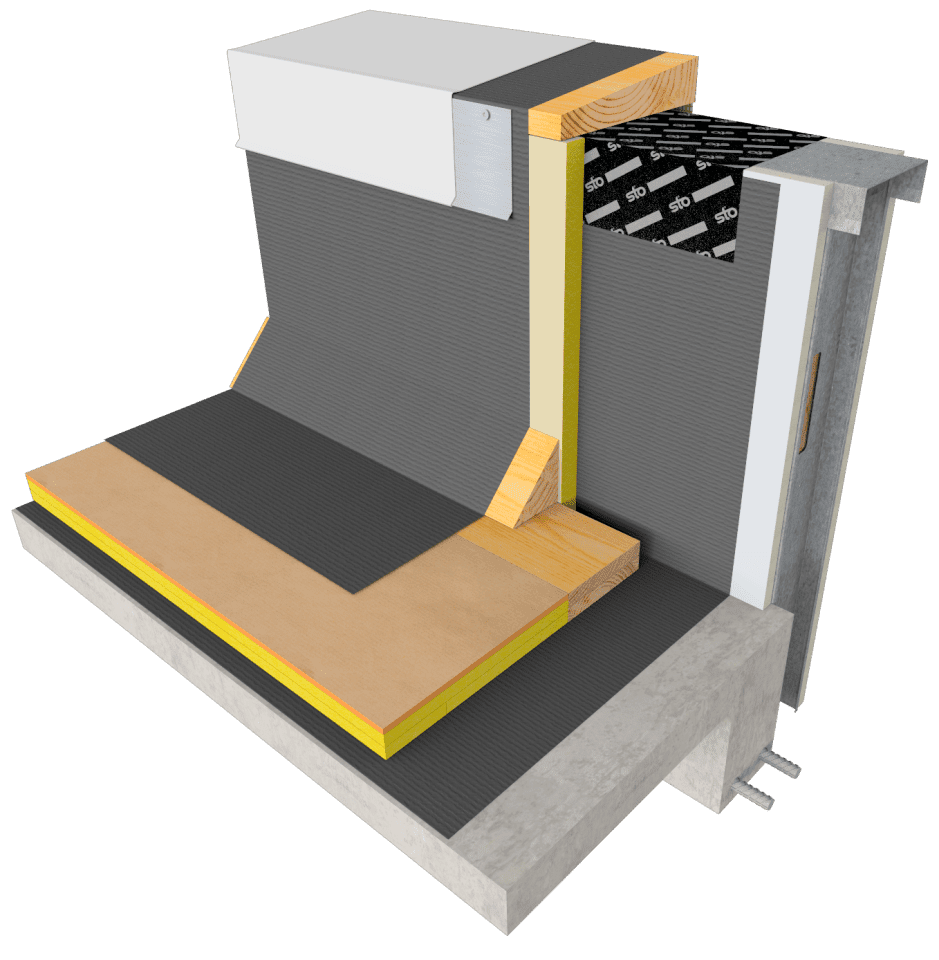

An AWRB is a continuous barrier across the entire building enclosure that resists both air and water intrusion. Preventing air leakage helps maintain a stable indoor environment and reduces energy consumption related to heating and cooling. Resisting water penetration protects against moisture-related issues such as rot, mold, and mildew.

All AWRBs are designed with the same goal in mind. However, there are several different types of materials for AWRB. We are focused on two common materials: fluid-applied and self-adhered. Let’s begin with the fluid-applied AWRB.

Fluid-Applied AWRBs

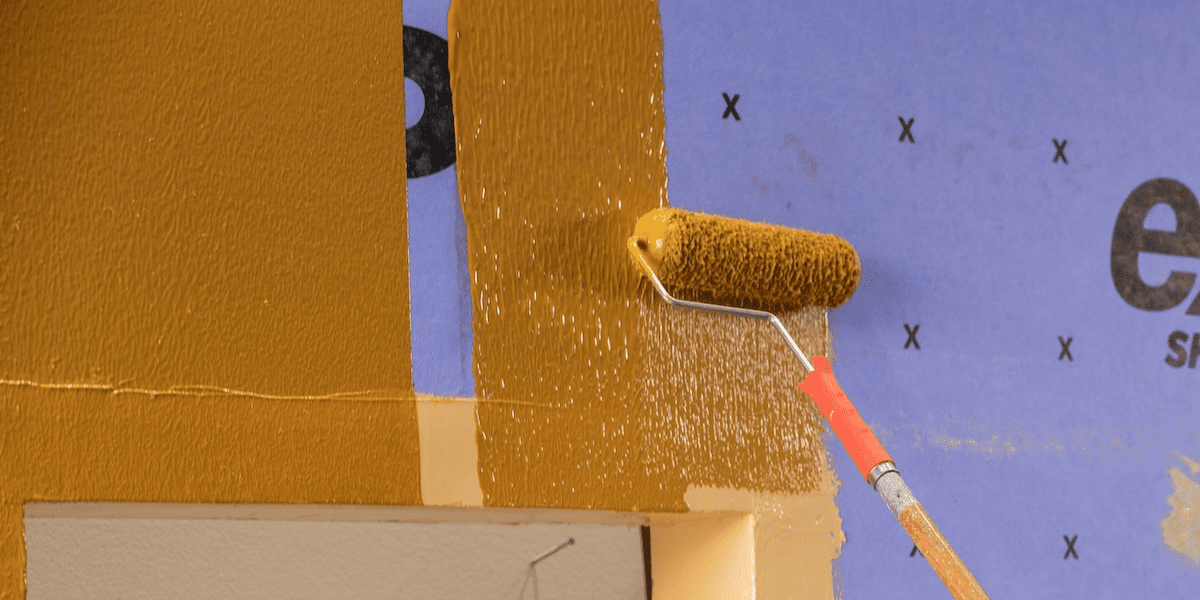

The fluid-applied AWRB is installed by either rolling or spraying a liquid membrane onto substrates, such as wall sheathing or concrete masonry units (CMU). The elastomeric or polymer-modified liquid cures into a monolithic barrier offering seamless flexibility.

Key benefits of the fluid-applied AWRB include:

- Seamless coverage, ideal for complex geometries and penetrations

- Time- and labor-efficient for large-scale, straightforward walls

- Good substrate flexibility and adaptability across materials with no mechanical fasteners or additional adhesives

As mentioned earlier, each material type has its own set of tradeoffs. Challenges for the fluid-applied AWRB are:

- Thickness control and weather dependence

- Curing time can delay follow-on trades

- Skilled application required for consistent performance

Now that we know the advantages and disadvantages of the fluid-applied AWRB, let’s sum it up. The best-use case scenarios for this material type include:

- Irregular geometries

- High-production installs

- Warm-weather installs

- Retrofit over CMU or rough surfaces

Self-Adhered AWRBs

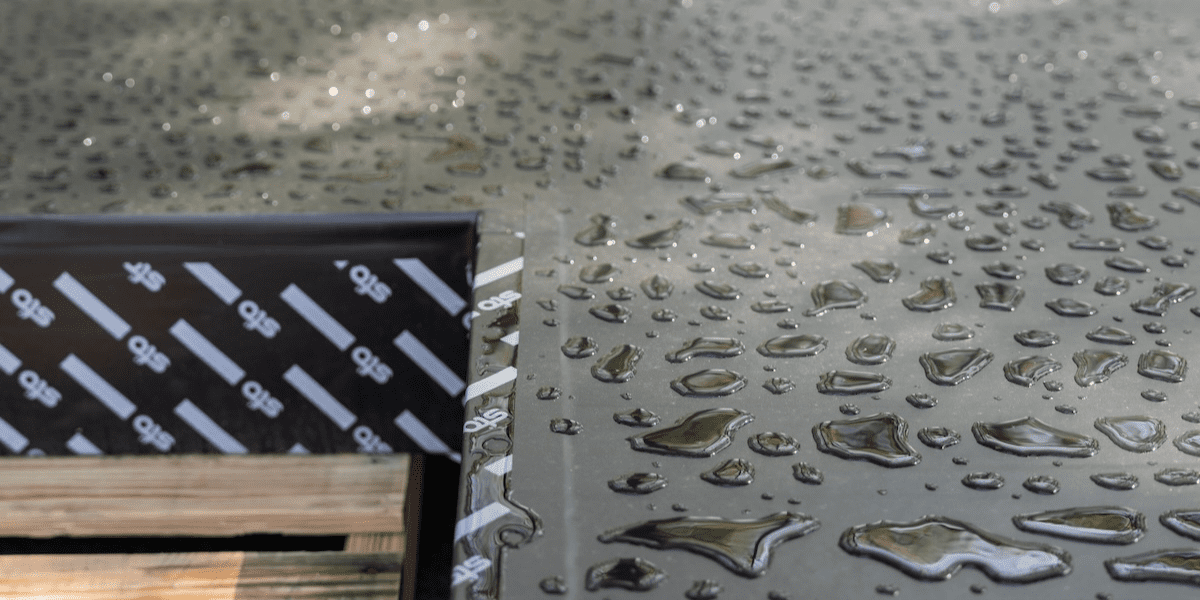

Self-adhered AWRBs are commonly referred to as peel-and-stick membranes. These membranes feature a sticky adhesive side (adhesives are typically acrylic, butyl, or asphaltic based) that adheres directly to the substrate, eliminating the need for mechanical fasteners or additional adhesives. The self-adhered AWRB offers both precision and durability.

Key benefits of the self-adhered membranes include:

- Uniform thickness, immediate waterproofing post-install, and no cure time

- UV and puncture resistance for exposed conditions

- More visual QA/QC opportunities

Challenges include:

- Difficult detailing around penetrations and edges

- Manipulating material in-place with adhesive exposed

- Wrinkling, bubbles, and seams can compromise performance if mishandled

The upshot? Self-adhered AWRBs best-use cases include:

- Straightforward assemblies

- Schedule-sensitive builds

- Exposed sheathing areas

- Code-driven durability priorities

High-Performance AWRB Solutions from the Experts at Sto

Sto is the innovative world leader in claddings, air barriers, coatings, and restoration systems. The StoGuard family of air and water-resistive barrier systems includes both fluid-applied and self-adhered membranes and, as such, takes a multi-solution perspective that doesn’t push one product over another, but instead ensures the best solution for each project.

Sto offers a variety of fluid-applied AWRB products, including Sto Gold Coat and Sto GoldSeal STPE. With over 250 million square feet of product installed, Sto Gold Coat can be used on a wide range of substrates, behind most wall claddings, and in varying thicknesses. Sto GoldSeal STPE, the newest fluid-applied membrane, offers moisture-cure chemistry for humid, cold, and wet climates.

Our self-adhered membrane solution is StoShield™SA, a high-performance, self-adhered air and water-resistive barrier available in two configurations: StoShield™ SA VP (vapor-permeable) and StoShield™ SA NP (non-permeable). Designed for instant waterproofing, consistent coverage, and cold-weather application, StoShield SA makes envelope design more precise and installation more efficient.

Both solutions are part of the StoGuard® air and water-resistive barrier system and, as such, are compatible with StoGuard® Detail Components – a set of accessories that provide durable air and waterproofing continuity at movement joints, substrate transitions, penetrations, and rough openings – and work with our proprietary wall systems. All of our solutions are fully tested and compliant with green construction codes and carry system warranty options.

Technical Support is Always Available

Choosing the right AWRB for your project is critical to long-term protection and performance. Now that you know the differences between fluid-applied and self-adhered AWRBs, you’re ready to make a more informed decision.

In the event you need help selecting the best AWRB for your scenario, Sto Corp. provides various technical services, including:

- Plan Review: Help with complex details, code conflicts, and construction alternatives.

- Detail Drawings: A library of guide details to assist in project planning.

- Wall Analysis: Calculations related to dew point, freeze point, ‘R’ value, and wall thickness to minimize condensation potential.

- Specifications: A library of guide specifications online in their Documentation Center.

- Technical Publications: Information on Sto products, technology, building science, and industry issues.

For more information on StoGuard® products and systems, visit our website. To contact a Technical Rep for project-specific recommendations and to answer your questions via phone, call 800-221-2397 or complete our contact form.