Even the best-laid expansion and renovation plans are riddled with logistical challenges, as they can disrupt ongoing operations, increase safety risks and extend project timelines. This is especially true for hospitals, office buildings and multifamily properties because there are so many people and daily activities to work around. Maybe an alternative to traditional construction is in order.

The Secret to Minimizing Disruption: Prefabrication

The problem with traditional construction is the banging, and the sawing, and the cutting, and the mess from it all. With prefabrication, panels are manufactured off-site in climate-controlled facilities, resulting in a more consistent, higher-quality product. Panels arrive ready to install, reducing installation time and allowing facilities to remain operational during the expansion or renovation, reducing disruption to operations.

The benefits of prefabrication include:

- Controlled environment results in more consistent quality

- Less work on the jobsite means less disruption to operations

- Reduced weather-related delays ensure more predictable schedules and tighter budgets

But not all prefabricated panel solutions are created equal. One solution delivers performance, safety and sustainability, while offering virtually unlimited design freedom. That solution is Sto Panel Technology.

Sto Panel Technology – A Trusted Solution from a Trusted Partner

Sto Panel Technology provides the construction industry with a smarter form of wall design and construction through partnerships forged between leading contractors, fabricators and Sto Corp. – the world’s number one manufacturer of building envelope solutions.

By creating branded, tested, proven and warranted prefabricated, finished wall panel designs, Sto Panel Technology provides customized, project-specific constructability solutions that are not available anywhere else. Our broad offering of fully engineered and tested StoPanel prefabricated wall panels are manufactured in quality-controlled factories. Design assist services and support allow for development of unique solutions to project-specific challenges, effectively managing cost, labor and schedule requirements while reducing risk and improving project outcomes.

Sto Panel Technology benefits include:

- The ideal solution for expansion and renovation projects that demand speed, quality and minimal disruption

- Reduces jobsite congestion and safety risks, an important factor in occupied building environments and projects with tight space constraints

- Meets or exceeds code requirements for fire, moisture and impact resistance

- Off-site fabrication reduces material waste and supports ESG goals by minimizing construction-related emissions

- Prefabrication limits operational downtime, reducing revenue loss during construction phases

Sto Panel Technology: Case Studies

Sto Panel Technology sounds too good to be true, right? But it is true! And we have the real-world stories to prove it. These are just a couple of recent examples of how Sto Panel Technology can make a huge impact on new builds, renovations and expansions.

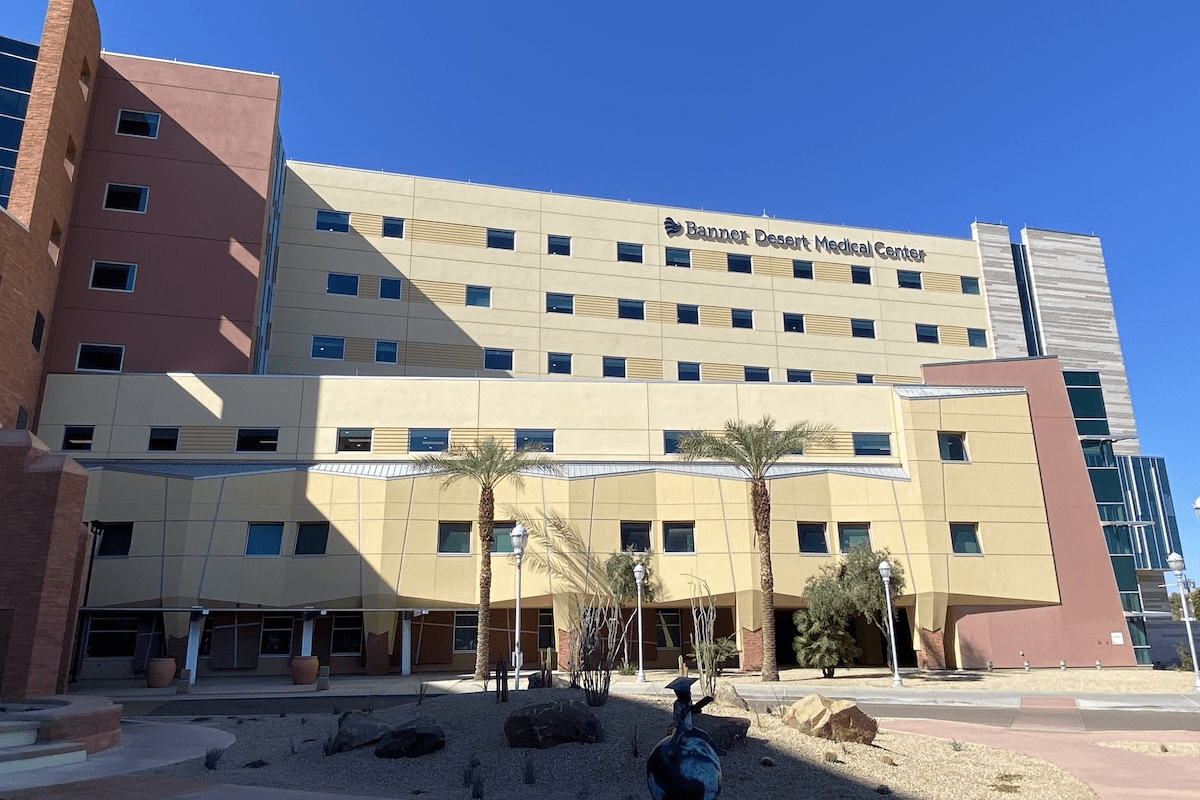

Banner Desert Medical Center

Location: Mesa, Arizona

Building Type: Healthcare

Construction Type: New

Banner Health’s Desert Mesa Campus established the need for a 58,550 sq ft expansion of the Women’s Tower and provided an opportunity for a multi-level addition. As the project required the construction of a new hospital wing above and adjacent to the existing hospital, with minimal disruption to the day-to-day operations of the existing facility, the need for prefabrication was obvious, and the entire project team adopted a panelized approach from day one.

MKB Construction used a wide variety of prefabricated exterior wall panels to achieve the multi-aesthetic facade, including StoPanel Classic NExT ci, StoPanel Metal ci and StoPanel Back-up with a masonry veneer. Composed of just over 135 panels, the facade for this project was installed in 4 weeks’ time.

Read the full case study here.

Centennial Hills Hospital Medical Center

Location: Las Vegas, NV

Building Type: Healthcare

Construction Type: New

Like most projects, the Centennial Hills Medical Center project originally called for panels to be built onsite. However, an aggressive 40-day installation and the hospital’s location in a residential neighborhood, which made debris containment especially concerning, forced the construction team to reconsider that option.

To address these challenges, they moved fabrication of the 57,092 sq. ft. of StoPanel® Classic ci panels from the jobsite to their facility, shortening the field schedule by 3 months. By moving to their facility, they were also better able to contain construction debris.

Read the full case study here.

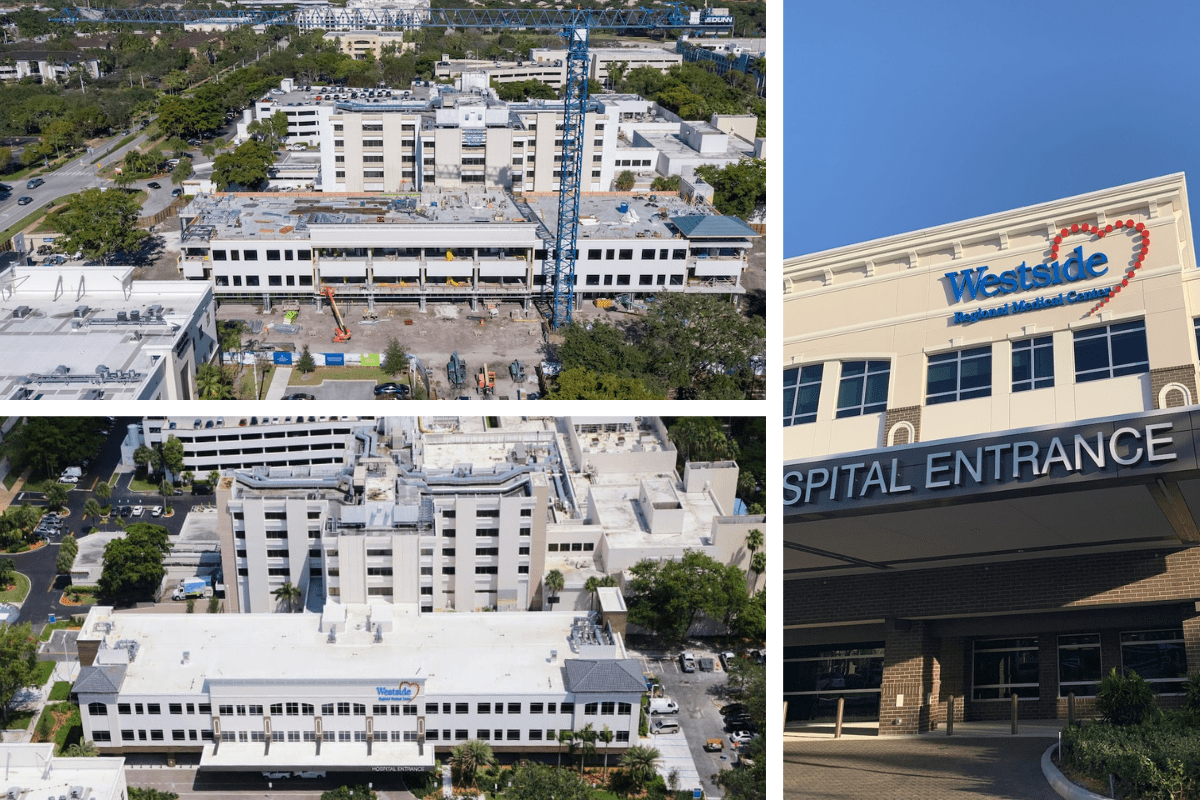

HCA Westside Regional Medical Center

Location: Plantation, FL

Building Type: Healthcare

Construction Type: Expansion

Due to the frequency and threat of extreme weather in the area, South Florida has strict building

code requirements for High Velocity Hurricane Zone (HVHZ) areas and for essential structures such as healthcare facilities. This new addition to the HCA Westside Regional Center had to adhere to the strict Florida Building Code and Notice of Acceptance (NOA) standards, especially for wind-load design and impact resistance requirements. As with most healthcare facilities, meeting or beating the schedule was also of utmost importance.

The StoPanel® Impact ci assembly allowed FLC Off-Site Construction to incorporate design

requirements and specifications meeting the Florida Building Code and Notice of Acceptance

(NOA) criteria directly into the design and fabrication process. Plus, they were able to install 22,000 square feet of panels in just 14 days.

Read the full case study here.

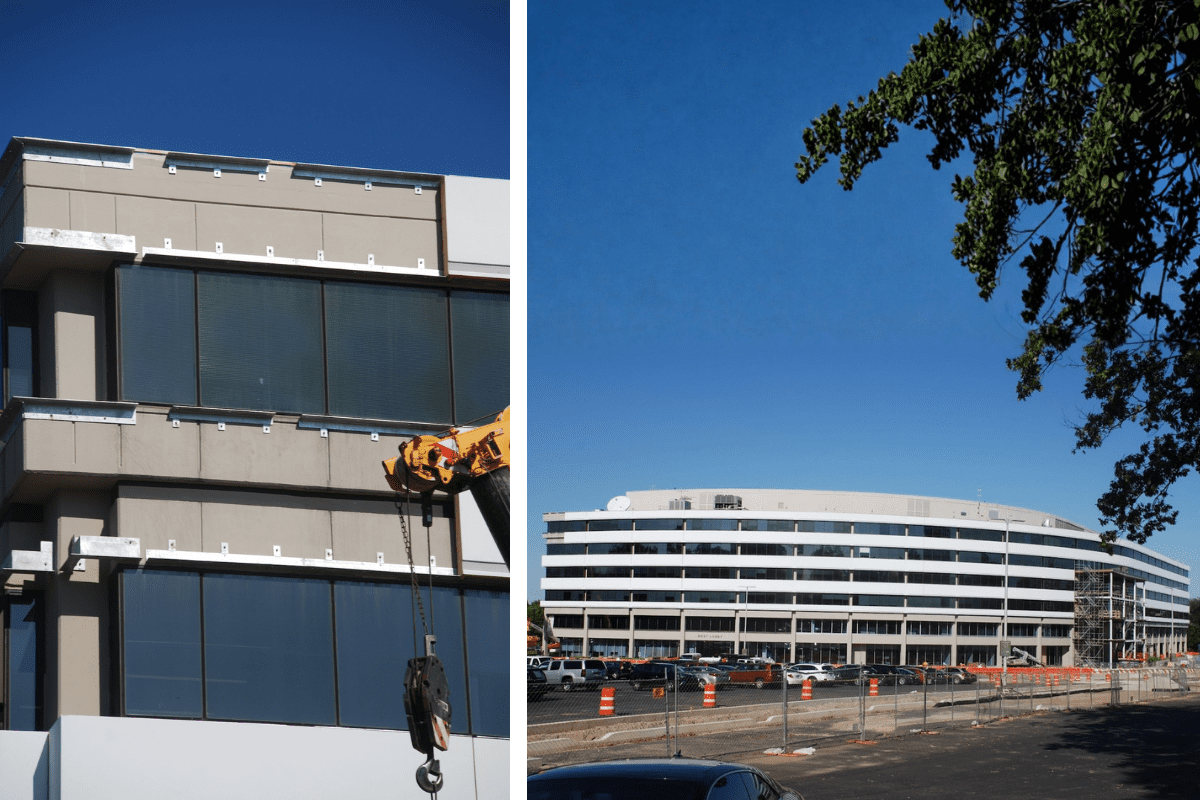

One Bala Place

Location: Bala Cynwyd, PA

Building Type: Office

Construction Type: Renovation

Built in 1965, One Bala Plaza was an aging, poorly insulated office building. Its restoration included 40,000 sq. ft. of custom-engineered StoPanel® Classic NExT ci panels installed over the existing façade, delivering a fresh look and vastly improved thermal performance.

The team decided to build a completely new exterior facade right over the existing structure.

Steel angles were bolted along the entire perimeter of the building, then the StoPanel® system and the new double-glazed ribbon windows were mounted in between. To avoid disturbing tenants, Jersey Panel limited installation to third shift and Saturdays. And by fabricating at Jersey Panel’s offsite facility, installation was complete in only 3 months, further minimizing disruptions.

Read the full case study here.

The Secret to Less Disruptive, More Predictable Expansions and Renovations: Sto Panel Technology

Expansions and renovations pose a host of challenges, especially in occupied buildings. Prefabrication is smarter, faster and less disruptive. And Sto Panel Technology delivers proven energy performance combined with unlimited design possibilities, enabling owners to go up while keeping their businesses running.

To learn more about Sto Panel Technology, visit our website or Sto Panel Technology Support.